The MACS Cooler (Modular Automated Cooling System) is an automated forced-air precooler. The MACS is designed to cool a variety of fresh fruits and vegetables prior to shipping.

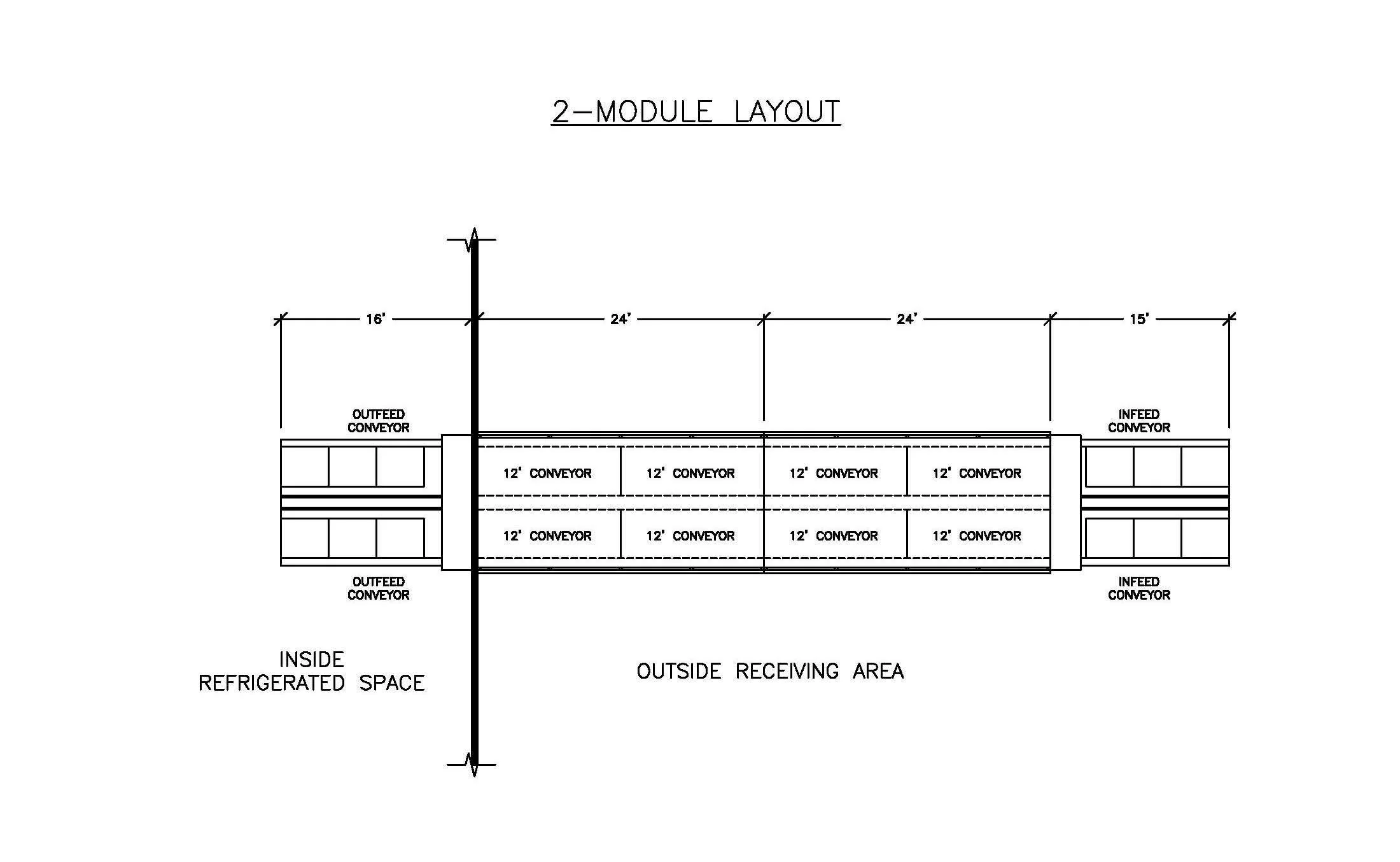

Typically, a MACS Cooler is attached to a refrigerated building. Pallets of product are loaded onto the MACS Infeed Conveyors, where they are automatically loaded into a cooling module.

MACS is Modular

This means that the primary sections of a MACS can be removed and reattached for portability and/or expansion.

MACS is Automated

MACS is the most sophisticated forced-air precooling system available. A load of 6 pallets is loaded by forklift onto the Infeed Conveyors. Then, the product’s pulp temperature is taken and entered into the Touch Screen. MACS takes it from there. The door opens, the seals retract and the load moves into the first cooling zone. All of this happens automatically.

MACS Coolers allow for a huge variety of product types through user-configurable recipes (we call them Product Codes). Product Codes contain temperature setpoints and safeties, fan speeds, cooling time and more.

And the features keep adding up! When we make improvements and add functionality, MACS Coolers are eligible for free software upgrades. This is just one of the ways we are able to innovate continually.

MACS is Cooling

From the time the product enters into the first cooling zone, MACS is cooling. Precooling with a MACS Cooler is really cooling. Because there is no room air to mix with, MACS Coolers can cool quickly. Plus, as the product moves from one zone to the next, the air-flow changes direction for more even cooling throughout the pallet.

MACS is a System of technologies and innovation

Every component in the MACS Cooler has been engineered or selected for cooling efficiency and reliability. MACS customers enjoy an uptime of 99.96%!! With over 12 years of innovation and nearly 50 installed units, MACS comes with the experience to find the ideal precooling configuration for your product.

Loading product into a MACS Cooler

Below, we take a look at the air flow inside a MACS Cooler. After a load of product automatically moves from one zone to the next, the air flow changes direction producing an even temperature throughout the product.

Reversing the air-flow direction equalizes the temperature across the pallet.

MACS Coolers cool faster and take up less space than conventional cooling tunnels.

The majority of the MACS Cooler sits outside the Cold Room, saving cooler floor space.

A 2-module MACS Cooler. Roughly 80% of the MACS is outside the refrigerated building.

MACS Coolers can be installed with 90° conveyors so the cooler can run parallel to the building.

Request a quote to see if a MACS Cooler is a good replacement for your cooling tunnels.